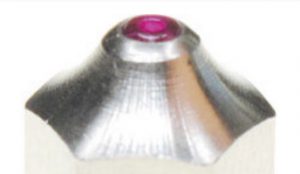

3D printing has become a mainstream form of manufacturing and production that is becoming even more prevalent as technology advances. A critical component of any 3D printer is the nozzle. This part is the source from which the filament flows from the machine to the surface. Nozzles can come in many different materials, ranging from brass to copper and steel. At the very tip of the 3D printer nozzle is the nozzle orifice. The orifice is critical to delivering the material to the surface in a consistent size and flow. Many 3D printers use jewel orifices due to the ability to maintain a tight tolerance and a small opening.

Some 3D printing filament contains hard, sharp particles like glass, sand, and carbon fiber. These materials have high levels of abrasiveness and will damage the nozzle and orifice over time.

Sapphire and Ruby are excellent orifice jewel materials because of their resistance to wear, heat and corrosion, as well as low friction.

Sapphire and Ruby are excellent orifice jewel materials because of their resistance to wear, heat and corrosion, as well as low friction.

Additionally, 3D printed objects with many “islands” or cross-sectional areas that are not connected, will wear the nozzle much faster than simple structures. The nozzle face and tip will rub against the printed part when it moves from one outline to the next. The continual abrasive action will result in damage over time. By using a sapphire or ruby jewel tip, the wear and abrasion damage are minimized, resulting in longer nozzle life.

Other applications for sapphire and ruby jewel orifices, orifice nozzles, and orifice valves:

– Ultra-High-Pressure (UHP) water jet applications (up to 40,000-50,000 PSI)

– Oil atomizing

– Air handling and hot gases

– Liquids and acids

– Gas/liquid control valves

– Analytical Instruments

– Flowmeters

– Pneumatic Regulators

– Ink-Jet Printing

Henyuan Sapphire Optics has stock sapphire and ruby orifice jewels and custom designs to utilize with 3D printing nozzles and other application components that require tight tolerances for the orifice. We can create a wide range of custom components from internal holes and tapers to outer flanges, angles, and surface finishes. Contact us to review your sapphire nozzle or sapphire orifice component needs.