[email protected]

Sapphire’s attributes include high mechanical strength, temperature stability, wear resistance and chemical inertness. As a result, a Sapphire Window will exceed other optical materials in harsh environments, providing a barrier between elements. Sapphire Windows are used commonly in optical and mechanical applications. Our offering includes a wide range of Sapphire Window stock parts as well as sapphire window customization opportunities.

Request more info on optical window applications.

Explore our extensive selection of Sapphire Window stock parts and order online today. Need something custom? We specialize in creating a wide range of custom optical and mechanical components, from internal holes and tapers to outer flanges, angles, and surface finishes. Contact us for a consultation and we’ll create a custom component that meets all your specifications.

Evaluating if utilizing sapphire windows is the right material for your project? Review our collection of articles and guides:

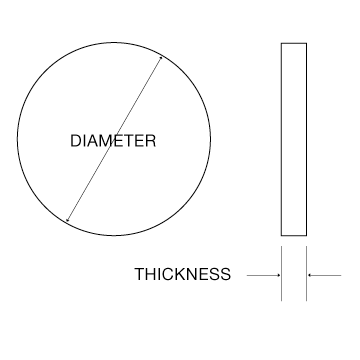

| Model | Diameter | Thickness | Material |

|---|---|---|---|

| W1.60 | .062/.063” | .010/.012” | Sapphire |

| W75.20 | 2.948/2.952" | ..077/.081" | Sapphire |

| W63.25 | 2.490/2.510" | .248/.252" | Sapphire |

| W51.00 | 1.998/2.002” | .245/.255” | Sapphire |

| W50.00 | 1.998/2.002” | .123/.127" | Sapphire |

| W40.00 | 1.565/1.585" | .075/.083" | Sapphire |

| W41.30 | 1.620/1.630” | .039/.041” | Sapphire |

| W49.95 | 1.998/2.002” | .038/.042” | Sapphire |

| W35.00 | 1.368/1.388" | .035/.043" | Sapphire |

| W33.00 | 1.365/1.385” | .165/.175” | Sapphire |

| W38.00 | 1.490/1.510” | .039/.041” | Sapphire |

| W38.10 | 1.490/1.510” | .124/.126" | Sapphire |

| W28.60 | 1.250/1.252” | .019/.021” | Sapphire |

| W30.00 | 1.171/1.191" | .035/.043" | Sapphire |

| W31.80 | 1.245/1.255" | .039/.041” | Sapphire |

| W26.67 | .998/1.002” | .039/.041” | Sapphire |

| W26.75 | .999/1.001” | .079/.081" | Sapphire |

| W26.90 | .995/1.005” | .370/.380" | Sapphire |

| W26.80 | .999/1.001” | .124/.126" | Sapphire |

| W25.50 | .995/1.005” | .019/.021” | Sapphire |

| W25.65 | .998/1.002” | .085/.092" | Sapphire |

| W25.00 | .982/.986” | .088/.092" | Sapphire |

| W24.76 | .973/.978” | .039/.041” | Sapphire |

| W23.80 | .936/.938” | .039/.041” | Sapphire |

| W22.50 | .895/.905” | .194/.199" | Sapphire |

| W22.23 | .866/.868” | .0386/.0409" | Sapphire |

| W22.20 | .855/.866” | .0740/.0838 | Sapphire |

| W20.00 | .7854/.7894" | .0747/.0827" | Sapphire |

| W19.25 | .748/.752" | .250/.252" | Sapphire |

| W19.05 | .745/.755" | .035/.045" | Sapphire |

| W17.78 | .695/.705" | .038/.042” | Sapphire |

| W19.02 | .748/.756" | .0185/.0209" | Sapphire |

| W17.27 | .675/.680" | ..077/.081" | Sapphire |

| W16.00 | .623/.627" | .1855/.1895" | Sapphire |

| W15.88 | .624/.626” | .079/.081" | Sapphire |

| W15.75 | .624/.626” | .039/.041” | Sapphire |

| W15.50 | .624/.628" | .018/.022” | Sapphire |

| W15.00 | .5906/.6004" | .0748/.0827" | Sapphire |

| W14.30 | .557/.567" | .038/.042” | Sapphire |

| W13.25 | .500/.502” | .0885/.0906” | Sapphire |

| W13.15 | .499/.501” | .061/.063” | Sapphire |

| W13.08 | .500/.515” | .018/.022” | Sapphire |

| W13.50 | .498/.502" | .123/.127" | Sapphire |

| W12.77 | .497/.503” | .038/.042” | Sapphire |

| W12.75 | .499/.501” | .019/.021” | Sapphire |

| W12.65 | .499/.501” | .024/.026” | Sapphire |

| W12.57 | .495/.505” | .010/.012” | Sapphire |

| W12.55 | .487/.497” | .037/.041” | Sapphire |

| W12.00 | .468/.472” | .008/.012” | Sapphire |

| W11.11 | .433/.441" | .018/.022” | Sapphire |

| W10.00 | .3937/.4017” | .038/.042” | Sapphire |

| W9.53 | .370/.380" | .015/.025” | Sapphire |

| W9.58 | .373/.377” | .038/.042” | Sapphire |

| W10.16 | .399/.401” | .055/.057” | Sapphire |

| W9.35 | .3661/.3700” | .1830/.1870” | Sapphire |

| W9.30 | .3661/.3700” | .0275/.0323” | Sapphire |

| W9.10 | .357/.363” | .009/.011” | Sapphire |

| W7.87 | .308/.312” | .060/.065” | Sapphire |

| W7.85 | .309/.313” | .018/.022” | Sapphire |

| W7.75 | .297/.301” | .018/.021” | Sapphire |

| W7.62 | .291/.301” | .009/.010" | Sapphire |

| W7.00 | .2746/.2766” | .019/.021” | Sapphire |

| W7.49 | .293/.297” | .014/.016” | Sapphire |

| W7.10 | .280/.282” | .0045/.0055” | Sapphire |

| W7.05 | .272/.278" | .037/.043" | Sapphire |

| W6.34 | .244/.250” | .060/.065” | Sapphire |

| W6.60 | .260/.264” | .009/.011” | Sapphire |

| W6.36 | .249/.251” | .0898/.0906” | Sapphire |

| W6.35 | .249/.251” | .148/.152” | Sapphire |

| W5.00 | .1969/.2008” | .0374/.0413” | Sapphire |

| W6.33 | .249/.251” | .019/.021” | Sapphire |

| W6.30 | .247/.249” | .030/.032” | Sapphire |

| W4.07 | .159/.161” | .019/.021” | Sapphire |

| W4.75 | .186/.188” | .0332/.0352” | Sapphire |

| W4.62 | .182/.192” | .019/.021” | Sapphire |

| W3.81 | .145/.155” | .039/.041” | Sapphire |

| W3.43 | .1345/.1355” | .048/.052” | Sapphire |

| W2.48 | .0980/.0984” | .0179/.0215” | Sapphire |

| W0.94 | .0365/.0375” | .0034/.0046” | Sapphire |

We specialize in creating a wide range of custom optical components and custom mechanical components including a variety of shapes - from internal holes and tapers to outer flanges, angles and surface finishes. Contact us (800-922-0118) and we will consult with you to create a custom component that meets all of your specifications.

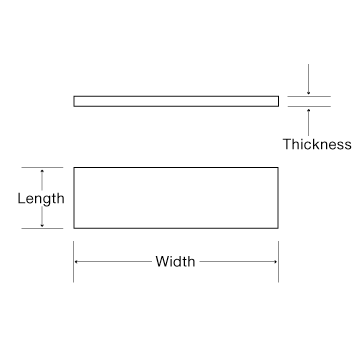

| Model | Length | Width | Thickness | Type |

|---|---|---|---|---|

| SP-110-2 | 1.49/1.51" | .999/1.001" | .009/.011" | polish both sides |

| SP-110-1 | 1.49/1.51" | .999/1.001" | .009/.011" | polish one side only |

| SP-112 | .361/.369" | .311/.319" | .0061/.0098" | sapphire window |

| SP-114 | 1.118/1.126" | .921/.929" | .014/.018" | sapphire window |

| SP-103 | .484/.516" | .130/.132" | .027/.037" | sapphire window |

| SP-103A | .484/.516" | .115/.122" | .027/.037" | sapphire window |

We specialize in creating a wide range of custom optical components and custom mechanical components including a variety of shapes - from internal holes and tapers to outer flanges, angles and surface finishes. Contact us (800-922-0118) and we will consult with you to create a custom component that meets all of your specifications.

We specialize in creating a wide range of custom optical components and custom mechanical components including a variety of shapes - from internal holes and tapers to outer flanges, angles and surface finishes. Contact us (800-922-0118) and we will consult with you to create a custom component that meets all of your specifications.

| Property | Sapphire | Fused Silica (Quartz) | Borosilicate Glass | Silicon Carbide (SiC) | Zinc Selenide (ZnSe) | Magnesium Fluoride (MgF2) |

|---|---|---|---|---|---|---|

| Optical Transparency | Excellent (UV to IR) | Excellent (UV) | Good | Poor | Excellent (IR) | Excellent (UV & IR) |

| Thermal Stability | Excellent | Good | Moderate | Excellent | Moderate | Good |

| Mechanical Strength | Very High | Moderate | Low | Very High | Low | Low |

| Chemical Resistance | Excellent | Good | Good | Excellent | Moderate | Good |

Here are seven current and popular applications of optical, sapphire windows: